Management of the building's internal lighting

The scheme, number and location of the building lighting control points is determined by:

a) the power circuit of the lighting installation;

b) the number and location of food points;

c) the purpose of individual parts of the illuminated building;

d) the necessary mode of operation of the lighting installation resulting from the production mode of work in a lit room or in separate parts of it;

e) architectural and construction characteristics of the lighted building, the location, in particular, of the entrances and exits, stairs, the presence and location of openings with natural light;

f) the presence and location of the control rooms for lighting management.

The question of the power supply of any enterprise is an independent big question, and here it will be considered only in that part of it, which defines a lighting control circuit.

Power circuits for lighting installations

Power circuits for lighting installations

Electric lighting networks are divided into supply, distribution and group networks.

Supply of lighting network - the network from the substation switchgear or branch from the overhead power lines to the input unit (VU), input switchgear (ASU), main switchboard (MSB).

Distribution network - network from VU, VRU, main switchboard to distribution points, panels and lighting points for power supply.

Group network — a network of shields to lamps, sockets and other electrical receivers.

The power supply of electric lighting is carried out, as a rule, in connection with power receivers from ordinary three-phase power transformers with a solidly grounded neutral and a nominal voltage on the low side equal to 400/230 V. Rated voltage in such networks it is 380/220 V.

The lighting installation can be powered both by separate lighting transformers and by common, combined transformers that simultaneously supply the power supply. Separate lighting transformers are rarely installed when power transformers supply loads such as welding machines or large motors, when switched on the voltage changes dramatically.

Power supply diagram for lighting and electrical loads

Group valve - a device in which protective devices and switching devices (or only protective devices) are installed for individual groups of lamps, plugs and stationary electrical receivers.

Group valve - a device in which protective devices and switching devices (or only protective devices) are installed for individual groups of lamps, plugs and stationary electrical receivers.

From switchboards to substations, power supply lighting networks are produced from independent separate lines. They are each powered by one or more group shields, depending on their power and mutual arrangement.When fed from a rack of three or more (group) shields they must be used with control devices at the entrance. In buildings without natural light, it is recommended to install the input devices on each of the panels of the lighting group, except when each shield is powered by an independent line.

Using the main lighting panel

With a large number of light lines for small loads, as well as with a limited number of panels, it is recommended to install the distribution board in or near the substation to feed the group shields lighting the main board connected by one line to the board. The trunk switchboard should also be installed at the entrance of the line in buildings with a large light load, remote from the substation.

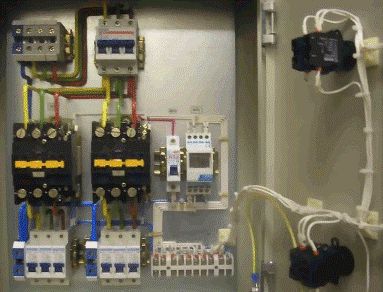

Group and main switchboards are equipped with protective and control devices: circuit breakers, automatic machines, magnetic starters and other devices, depending on the control system adopted for this lighting installation. With both local and remote lighting control from these panels, it is possible to turn on and off the illumination of the object in whole or in part.

It is preferable to have completely independent, separate power and lighting lines. There are many reasons for this, and in particular the difference in the mode of operation, the need for working lighting continues even during the periods when the load of the power supply and, accordingly, the electrical network is turned off for repairs, revisions, during non-working holidays, etc.

Power circuit for group panels through the main cabinet

Power circuit for group panels through the main cabinet

At the same time, when the power transformer is located at a long distance from a building with a low lighting load, separate power and lighting lines are irrational. In such a case, the cable feeding the lighting panels is connected to the input contacts of the power supply shields of this building. This ensures that the lighting output does not depend on the power supply of the electrical load. Near the power plant of the connected lighting, the power cable is equipped with protection and control devices. In fire-hazardous warehouses, such entrance boxes are installed outside the building.

The use of rack and distribution busbars to power lighting installations

Currently, in industrial enterprises, the distribution of electricity without intermediate screens is used quite widely - on the main and distribution bus channels. From these bus channels in different places, depending on the location of electricity consumers, cables go to power units through special boxes in fuses and circuit breakers.

Currently, in industrial enterprises, the distribution of electricity without intermediate screens is used quite widely - on the main and distribution bus channels. From these bus channels in different places, depending on the location of electricity consumers, cables go to power units through special boxes in fuses and circuit breakers.

When making a decision to supply lighting from the bus channels, it should be taken into account that at a certain moment they can be turned off and the lighting must continue to function. Therefore, the supply lines of the work lighting must be connected not to the secondary busbars, but to the head of the main busbars or to the switchboard of the transformer substation.

See also: Power circuits for lighting installations

Lighting panels and lighting control points

For ease of use and energy savings, the number of lighting control points should be as small as possible. Their number can be significantly reduced by focusing lighting control on group or main panels. In this case, local keys are kept only for separate closed premises (ventilation chambers, warehouses, office premises, etc.), as well as for production sites and areas that cannot be walked and are occasionally visited by their staff on maintenance (for example, for crane repair sites).

For ease of use and energy savings, the number of lighting control points should be as small as possible. Their number can be significantly reduced by focusing lighting control on group or main panels. In this case, local keys are kept only for separate closed premises (ventilation chambers, warehouses, office premises, etc.), as well as for production sites and areas that cannot be walked and are occasionally visited by their staff on maintenance (for example, for crane repair sites).

With a large number of panels spaced apart, the number of control points can be reduced by centralizing lighting control directly on the substation panels. This solution is usually recommended if the number of substations is not more than two.

In large industrial buildings with little or no natural light, centralized control should not be abandoned. lighting, since here too the switching on and off of electric lighting is done relatively often: during lunch breaks and between shifts, during repair work, etc. When working in several shifts, lighting control from a large number of panels, especially located in technical floors of buildings, becomes a complex problem, the solution of which, as a rule, is successfully achieved with the help of remote control lighting.

Network for group lighting

A very important issue when developing issues in a lighting management project is the breakdown of the total number of lighting fixtures installed in the room into separate groups.The correct solution to this problem predetermines the possibility of organizing a rational lighting control system and thus ensuring convenient operation of the lighting installation and economical use of electricity for lighting.

First of all, in rooms with side windows, it is necessary to control rows of lamps parallel to the windows. This makes it possible, with the onset of darkness, not to turn on all the lamps at the same time, but in parts: first in the part of the room away from the windows, and then, when the natural lighting decreases, in the rest of the room. It is the same in the morning hours: first a row of lamps next to the windows is turned off, and then, with an increase in natural lighting, row by row in the depths of the room.

When dividing the lighting installation into groups and therefore into independently controlled parts, the peculiarities and conditions of the production organization in the illuminated room should also be taken into account.

If in a large illuminated room there are several different and independent workshops or departments, then it is advisable to group the lamps in such a way that the workers from each of the shops can serve, turn on and off only their groups, their part of the lighting installation.

If the room has several production lines and different technological zones with different modes of operation, then you need to organize the management of groups of lamps in such a way that you can turn off some of them in those zones of the room, where according to the production conditions, they are not needed .

When dividing the lighting fixtures into groups, it should be borne in mind that in industrial buildings with a particularly dusty environment (sintering factories, cement plants, etc.) provides normal vision conditions during the day, which requires constant lighting throughout working hours.

In all production areas, it is necessary to provide for the distribution in separate or separate groups of a small part of lighting fixtures to create a room with little lighting during the time when the workshop is not working and it is only necessary to ensure the possibility of its guarding and cleaning. If there is in the room emergency lighting, then separate small groups of luminaires should not be allocated, as the "backup" lighting functions will be performed by emergency lighting luminaires.

Lighting control of automated workshops

Lighting control of automated workshops has specific characteristics. The group lighting network of automated workshops should be designed so that during periods when the workshop is not in production correctional work, it was possible to turn off part of the general lighting. General lighting installations of automated workshops must consist of two independently controlled parts. During the operation of both parts of the lighting installation, lighting is created in the workshop area, selected according to the standards for this workshop. When the majority of the installation is turned off, the "on-duty" part of it, which remains in the on state, provides enough lighting for general monitoring of the operation of the mechanisms.

Lighting control of automated, as well as other, workshops should be convenient to work, turning on and off the lamps should be done without much loss of time. In some cases, control circuits must provide the ability to turn lights on and off from not one, but two locations. In other cases, it is rational to concentrate management in one place — on the store manager's control panel. This will make it possible, when using television equipment, to turn on full illumination in order to get a clearer image of the controlled technological process on the television screen.

Step-by-step control of lighting fixtures

In industrial premises, depending on the number of lamps and lamp power, they use single-phase (phase and zero), three-phase (three phases and zero) and less often two-phase (two phases and zero) groups. It is recommended for three- and two-phase groups to provide step-by-step control of the lighting fixtures, that is, to install not three- and two-pole, but single-pole switches, which creates greater flexibility in lighting control. Of course, it is necessary, of course, to evenly and correctly distribute the lighting fixtures in phases.

In three-phase groups, the lighting fixtures are connected to the phases in the following order:

a) A, B, C, C, B, A... — if not necessary for zone management or for uniform dimming;

b) A, B, C, A, B, C ... — if it is necessary to provide, when one or two phases are turned off, fairly uniform reduced lighting over the entire area of the premises;

c) A, A, A, …, B, B, B, …, C, C, C … — if, however, in these it is necessary to maintain full lighting only in part of the workshop area.

Emergency lighting control

Emergency lighting should in all cases be managed by panels, the number of which should be as small as possible. In addition to panels, switches should be installed only in separate rooms that are not used for passages and where service personnel are not constantly present (meeting rooms, closets, normally closed production rooms).

Lighting control in residential buildings

In residential buildings, the power supply scheme must ensure the possibility of separate power supply for users of apartments and utility and other facilities. This makes it necessary to install, in addition to the entrance panel of the shield, two or three additional panels. It is more rational to use a single combined distribution point with the necessary switching and protection means. The power cable is connected to the distribution point through a switch, with which you can completely turn off the electrical network at home. The switching circuit of the switchboard provides separate supply for apartments, municipal and general consumers, stair lighting and outdoor lighting.