Fault finding in relay-contactor circuits. Part 1

Electricians of various professions manufacture, install, configure, repair and maintain various electrical equipment. In this case, an indispensable part of their work is the search for defects. The need for timely detection and elimination of defects is difficult to overestimate, because the more perfect and efficient the electrical equipment, the greater the economic damage from its downtime or irrational use, even for short periods of time. This is why the ability of electricians to detect defects in various electrical equipment is so important.

Word scheme is used to denote the documentation of an electrical installation or an electrical product. In case it is necessary to refer to any document, an explanatory word indicating the scheme in question will be added to that word.

If the circuit of a relay-contactor (for brevity, in the future a product or an object) meets all the requirements established in the documentation, then it is customary to say that it is in good condition... When there is no such correspondence, then they talk about defective products or for it malfunctions.

The transition of the product from a working state to a defective one occurs due to defects. Word defect used to indicate any individual non-compliance of the product with the requirements established for it in the documentation.

It follows from the definitions that it is impossible to remove the defect in the product, but it is possible to remove the defect in the product. If it is the only one, then the product will go to the upright state.

Defects in a product can occur at different times in its life cycle — during production, assembly, adjustment, operation, testing, repair, and have different consequences.

The consequences are distinguished as critical, significant and minor defects.

The presence of critical defects makes the intended use of the product impossible or unacceptable.

Example 1. Critical defect.

As an example product, we choose a DC relay for a nominal voltage of 110 V, whose coil has wx = 10,000 turns and its resistance Rx = 2200 Ohm.

Other parameters: rated current Inom = 0.05 A, operating current Israb = 0.033 A, safety factor Kzsh = 1.5, rated MDS (magnetic driving force) Aw = 500 A.

Let there be a defect in the coil that short-circuits 90% of the turns and reduces the resistance of the coil to R2 = 220 Ohm (assuming that all turns are the same length).

At a voltage of 110 V, this resistance will correspond to a current I2 = 0.5 A and MDS Aw2 = l2 * w2 = 0.5 • 1000 = 500 A.

Although the figures show that the value of MDS will not change and the relay will be able to attract its armature, any continuous operation of the relay with such a defect is impossible, because after applying the rated voltage to the defective coil, a coil of wire overloaded with current 10 times, it will burn almost instantly.

Significant defects limit the possibility of using the product for its intended purpose or reduce its durability (see example 6).

Example 2. Large defect

Suppose there is a defect in the relay coil discussed in Example 1 that causes 20% of the turns to close, that is, 8000 turns remain active in it.

Assuming that the proportionality between the number of turns and the coil resistance is still proportional, the resistance of the defective coil can be determined to be R3 = 1760 ohms.

This resistance at 110 V will limit the coil current to I3 = 0.062 A.

Therefore, MDS Aw3 = 0.062 • 8000 = 496 A.

Thus, even with this defect, the MDS will be sufficient to operate the relay, but increasing the current through the coil by almost 25% will cause the coil to overheat beyond what is allowed for its insulation and prematurely fail the relay , although it will be able to work for a while.

If the presence of a defect does not affect the performance of the product, then it is called minor.

Example 3. Small defect

In the relay coil, the parameters of which are given in example 1, 5% of the turns are short, the resistance of which is approximately equal to 2090 Ohm.

This resistance will limit the current in the coil to a value of I4 = 0.053A, which corresponds to MDS Aw4 = Um W4 = 503 A.

Given that the relay documentation has a 10% tolerance for rated current, ie. Inom max = 0.055 A, then the 0.003 A increase in current cannot reasonably be attributed to a defect in the relay or its coil, since I4 < Inom max.

Due to the fact that the increase in current does not exceed the permissible for this relay, the defect that caused it does not affect the operation of the relay.

The considered examples show that not only different defects, but also the same type of defect (in our case, a short circuit of the coils turns) can have different consequences. The mere presence of a defect in a product does not always affect its ability to perform its functions.

In support of the above we will give an example where a string of electric lamps is considered as an object. This fairly simple object will be used in a few more examples when looking at the basic technological problems of defect hunting.

The simplicity of the object will allow, without being distracted from the explanation of the principle of its operation and the processes taking place in it, to pay attention only to the questions of searching for defects.

Example 4. Different manifestations of the same defects.

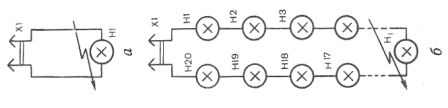

Let the object, which is a portable lamp (Fig. 1, a), have a short circuit between the terminals of the lamp.

Rice. 1 Different manifestation of the same defects: a — in a portable lamp, b — in a garland of electric lamps

When the light fixture is connected to a power source, a short circuit will occur in the source. In this case, from the point of view of the consequences, a short circuit in the lamp is a critical defect.

Another object is a garland of electric lamps (Fig. 1, b). The same defect in this object can lead to different consequences depending on the number of lamps in the garland.

In particular, with 25-30 or more lamps and the sum of their rated voltages exceeding the mains voltage, a short circuit in one of the lamps will not lead to an increase in voltage above the allowable voltage for each of the other operating lamps and to a noticeable increase in brightness on the other lamps.

Although externally, both defects manifest themselves in the same way (without lighting of the defective lamp), as a result, a short circuit in one of the lamps of the garland does not lead to a short circuit of the power source, and for the whole garland it is, according to the accepted classification , minor defect.

In addition to serviceable and defective states in technical diagnostics, a distinction is made between working and non-working states.

An effective product is considered capable of performing its assigned functions while maintaining the values of the specified parameters within the predetermined limits.

Otherwise, the product does not work.

Although every serviced product is simultaneously serviced, it is not always possible to say that a serviceable product is serviceable.

Examples 3, 4 show that defective products can also perform their assigned functions.

Violation of the serviceability of the product while maintaining its operability occurs as a result of damage, and in the case of malfunction - due to damage.

It follows from the above definitions that although the failure of a product is caused by the presence of certain defects in it, the occurrence of a defect in itself does not always lead to failure (see examples 3, 4).

Damages that are not related to a malfunction of other elements are called independent and occurred as a result of another, - dependent.

Example 5. Dependent refusal.

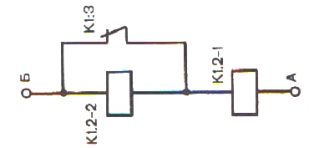

Some types of contactors use sectioned coils (Fig. 2).

Rice. 2 Sectional winding

When the contactor is turned on, the section of the coil K1.2-1, called the initial or on, operates. The second section of the coil K1.2-2 at this time is shunted by the opening contact K1: 3 of the contactor. Depending on the size of the contactor, the current flowing through the starting section reaches 8-15 A.

After the moving system of the contactor moves to the end position, the contact K1.3 will open and the holding coil K1.2-2 will turn on, and the current will decrease to 0.2-0.8 A.

Suppose there is a defect in the contactor that prevents contact K1: 3 from opening.

In this case, some time after applying voltage to the coil, the wire with which the closing coil is wound will burn out from overload. The conductor of this coil is only intended for short-term, fraction-of-a-second operation during the period when the contactor is on. Thus, a defect in contact K1: 3 leads to contactor failure.

Depending on the reasons that caused the occurrence of damage, they are divided into systematic and random.

Systematic damage to products occurs when the technological processes of their production or assembly, adjustment or operation, repair or testing are violated. The causes of such failures can be identified and corrected.

The occurrence of accidental damage is, although undesirable, a completely natural phenomenon and is characteristic of any technical object.

The probability of such failures is determined by its reliability indicators: MTBF, probability of trouble-free operation, durability, etc.

Let us illustrate the relationship of some of the above concepts.

Example 6. MTBF and Longevity

«Sometimes a new installation immediately fails or works poorly. In such cases, take the necessary measures immediately. Or at first everything is fine, then the performance worsens, and finally a failure occurs: the electrical installation fails, for example, after 3 months, although its service life is 16 years. "...

Here are two characteristics of reliability — MTBF (time to first failure) and durability (service life). In accordance with the accepted system of concepts for repairable products, MTBF is always less than their service life. Thus, if MTBF is set for a product less than or equal to 3 months, then its failure is natural. In the same case, when the established MTBF exceeds 3 months, we can talk about the low real reliability of this product.

The situation is different with non-repairable products, for which the MTBF must always be no less than their service life. Thus, failure of a non-repairable product with a service life of 16 years after 3 months of operation is abnormal.

The situation is different with non-repairable products, for which the MTBF must always be no less than their service life. Thus, failure of a non-repairable product with a service life of 16 years after 3 months of operation is abnormal.

However, it should be remembered that all reliability indicators characterize random values, and therefore the premature failure of a single product cannot reasonably assess the reliability of other products of this type.

In example 3, the case where a defect in the product is not manifested externally is considered. How can you find out about the presence of this or another defect in a certain product without waiting for a breakdown, accident or other undesirable consequences?

First of all, a defect in a product is manifested during its adjustment, testing or during a planned preventive inspection based on signs that allow establishing the fact of a violation of its operational or workability.

Based on these characters, the actual state of the product refers to one of the four states mentioned above (working, defective, effective, non-working) or to a borderline state where it is impractical to carry out any adjustments or repair work and the product must be replaced with a new one.

The above-mentioned signs are usually called defect criteria and they are laid down in the product documentation in the form of a list of parameters or characteristics with an indication of the permissible limits of their change — tolerances.

Oleg Zakharov "Searching for defects in relay-contactor circuits"

Continuation of the article: