Regulating properties of electric motors

Regulating any value of a physical process (any parameter) means maintaining a given value at a given level or changing it in accordance with a given law.

Regulating any value of a physical process (any parameter) means maintaining a given value at a given level or changing it in accordance with a given law.

Individual actuators or production mechanisms require different rotational speeds of the actuator motors for normal operation.

For example, each section of a paper machine must rotate at a strictly constant speed regardless of load changes, and the drive must be able to maintain this speed and smoothly change the speed of each section individually and of the entire paper machine as a whole.

The speeds of electric motors are regulated in different ways. This is necessary to know for the correct choice of drive motor for propulsion. Drives differ in the dependence of the values of power and moment on the shaft on the magnitude of the speed.

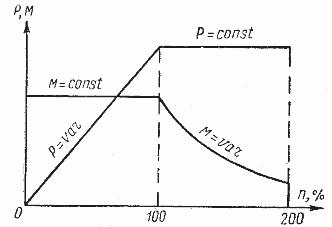

Some mechanisms maintain a constant torque value as the speed changes. These include, for example, metal cutting machines… In this case, the power changes in proportion to the speed of rotation (graphically, it is depicted by a straight line in Fig. 1).

Rice. 1. Speed control curves at constant power and constant torque

Other mechanisms require a constant power P when the speed changes (eg lifting and transport mechanisms). In this case, the magnitude of the moment changes according to the hyperbola law.

You can build graphs using the formula P = Мω10-3kWh,

where: M is the moment of the shaft, N x m, ω = (2πn) / 60 — angular velocity.

In fig. 1 shows the combined curves where as the speed changes from zero to rated, the torque remains constant. In this case, the power grows along a straight line passing through the origin. Then, with further increase in speed, the power remains constant and the moment decreases according to the law of hyperbola.

Read also: Mechanical characteristics of electric motors and production mechanisms