Electric drive using different types of electromagnetic clutches

For installations requiring rotation speed regulation using the simplest machines and devices, electric drives with electromagnetic clutches of various types can be used.

They are the most common electromagnetic slip clutches, with the help of which it is relatively easy to protect the elements of a working machine from damage with a sharp increase in loads, adjust the rotation speed, obtain special characteristics and improve the starting properties of an electric drive when using motors with a small starting torque (squirrel rotor induction motors and synchronous motors).

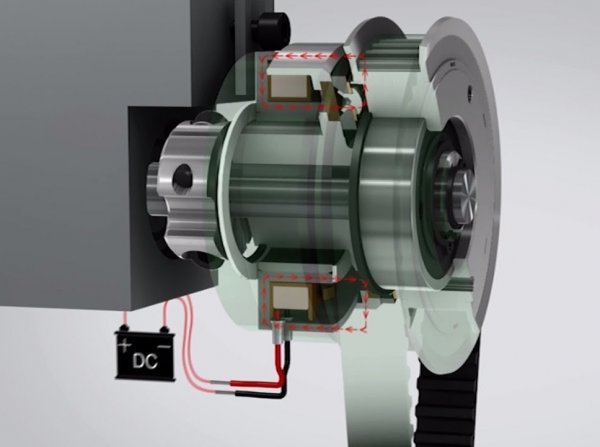

An electromagnetic slip clutch is an electrical machine consisting of two parts, an inductor and an armature, which are concentrically arranged and separated by an air gap.The part of the clutch firmly connected to the shaft of the electric motor is the drive part, and the second part connected to the drive shaft of the working machine is the driven part.

An inductor has poles with an exciting coil that receives power from a DC source through slip rings. The armature is a magnetic circuit made of sheet electrical steel, with a short circuit winding in the form of a squirrel cage.

The principle of operation of the clutch is the same the principle of operation of a multiphase asynchronous motor… But in an induction motor, a rotating magnetic field is created by means of a polyphase winding supplied by an alternating current source with a corresponding phase shift, and in a slip clutch the poles rotate with a constant magnetic flux relative to the short circuit.

In this coil, under the action of a magnetic flux, emf alternating current, amplitude and frequency which depends on the difference between the speeds of the driven and driven parts of the clutch, a current occurs and a torque occurs.

By changing the current in the field winding, it is possible to obtain different mechanical characteristics, representing the dependence of the transmitted torque on the clutch slip, which are similar to the mechanical characteristics of a polyphase asynchronous motor when adjusting the voltage supplied to it.

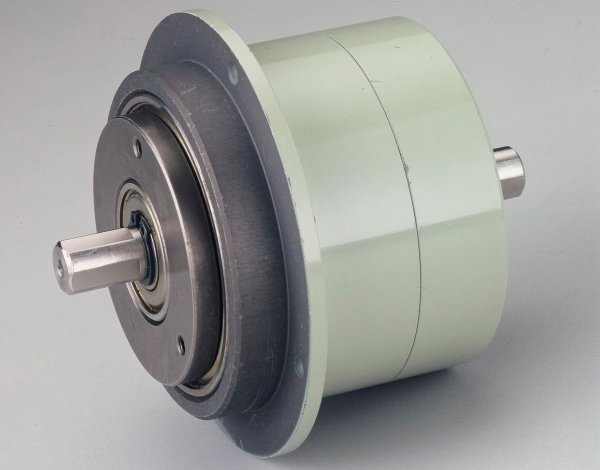

The simplest design has an electromagnetic clutch with a solid steel core armature. The torque of this clutch is generated eddy currents induced in the core.

This design of the connector significantly increases its reliability, since a massive core, heated by eddy currents flowing in it, has direct contact with the external environment, and the heat is better removed from the connector.

Typically, the inductor is the internal part of the connector fitted with protruding posts with a field winding supplied through the slip rings with direct current.

The mechanical characteristics of an electromagnetic coupling with a massive magnetic circuit, due to its significant resistance, have the form of the rheostat characteristics of an induction motor.

If it is necessary that the torque of the coupling remains approximately constant, regardless of the amount of slip, then the poles of the inductor are made of a special shape - in the form of a beak or a claw.

A relatively small amount of power is consumed to excite the clutch, which is not proportional to the power transmitted by the clutch and varies from 0.1 to 2.0%. Smaller numbers refer to high power connectors and larger numbers to low power connectors. So, in a coupler that transmits a power of 450 kW, the excitation losses are 600 W, and in a coupler for a power of 5 kW - about 100 W.

An electromagnetic clutch system provides the necessary speed control range, usually by varying the current in the inductor coil. But the efficiency of the drive in this case will be less than when adjusting the rheostat. This is because the overall efficiency of the drive is equal to the product of the efficiency of the clutch itself and the efficiency of the motor.

The coupling losses are mainly determined by the slip losses generated in the coupling armature. In the case of powerful couplings, it is necessary to have a special device to remove a significant amount of heat.

Electromagnetic clutches offer valuable properties combined with reliable operation asynchronous squirrel-cage motor.

A squirrel-cage motor has a relatively low starting torque, a significant starting current, and a sufficiently high critical torque. Therefore, with the help of an electromagnetic clutch, the engine can be started in the absence of current in the excitation coil of the clutch, i.e. when the torque transmitted by the clutch is zero. In this case, the engine quickly accelerates without load and its heating is insignificant.

After the motor moves to the working part of the characteristic, a current is supplied to the excitation coil of the clutch, which causes the appearance of an electromagnetic moment in it. The driven part of the coupling will remain stationary until the moment transmitted by the coupling exceeds the static load moment.

At the same time, the drive part of the clutch will load the engine with a torque of the same magnitude as that applied to the driven part of the clutch. In this case, the motor can develop a torque close to the critical and significantly exceeding its starting torque, and the motor current will be less than when starting.

Therefore, the use of an electromagnetic clutch is improved starting properties of the electric motorI am.Similarly, the starting properties of a synchronous motor, which are much worse than those of a squirrel-cage induction motor, can be improved.

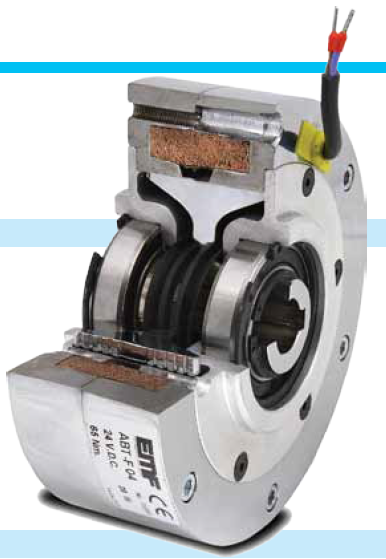

One of the varieties of electromagnetic clutches are connectors filled with magnetic powders… The main difference between the powder clutch and the slip clutches described above is that the iron powder (usually mixed with oil) is placed between two rotating parts of the clutch enclosed in a sealed housing.

If the field coil is not energized, then the iron powder is in a disordered state. When a current is supplied to the excitation coil, then under the action of its magnetic field, the dust will be located along the magnetic lines of force, forming a kind of circuits that close the air gap and ensure the transfer of power from the leading part of the clutch to the drives. The larger the excitation current, the greater the torque the clutch can transmit.

The electromagnetic powder clutch provides not only starting, but also speed regulation, and can also be used as a safety clutch that limits the maximum torque transmitted to the shaft of the working machine.

Due to the high magnetic permeability of iron dust compared to air, coupling requires significantly less excitation power than induction coupling.

According to the method of supplying current to the field windings, contact and non-contact dust connectors are distinguished. In contact connectors, the excitation coil is located on the rotating part, and the coil is energized through the slip rings.

The excitation coil of non-contact connectors is placed on the stationary part of the magnetic circuit, separated from the rotating elements by a small air gap.

In some cases, both powder and induction electromagnetic clutches are built into the bodies of the work machine, similar to custom electric motors, or combined in a common design with their drive motor. With this solution, the dimensions and weight of the drive are significantly reduced.

In some cases, hydraulic clutches or torque converters are used instead of electromagnetic clutches. Then the drive is called hydraulic.

Recently, in the modernization of the electrical equipment of metal cutting machines, machines and other various production mechanisms, an electric drive is replaced by induction and powder couplings of a frequency-controlled electric drive using squirrel-cage induction motors driven by through frequency converters.