Selection of the main parameters and elements of the power supply system of industrial enterprises

Electricity supply is the supply of electricity to consumers, and the power system is a set of electrical installations designed to provide consumers with electricity. The power supply system can also be defined as a set of interconnected electrical installations that supply a region, city, enterprise (organization).

The purpose of creating a power supply system — to provide consumers with electricity of appropriate quality with acceptable reliability indicators.

Choice of food methods and energy intake points

Supplying industrial enterprises with an installed capacity of energy consumers from 5 to 75 mW through one reception point is recommended to be carried out with a compact arrangement of consumers, and through two reception points - if there are two relatively powerful and separate groups of consumers at the facility.

Supplying industrial enterprises with an installed capacity of energy consumers from 5 to 75 mW through one reception point is recommended to be carried out with a compact arrangement of consumers, and through two reception points - if there are two relatively powerful and separate groups of consumers at the facility.

When the voltage of the supply network is different from the voltage of the distribution network, the main step-down substation (GPP) is taken as the receiving point. At the same voltage of the networks, a central distribution point (CRP) is provided as a receiving point.

For the power supply of small enterprises with an installed power of up to 10 mW electrical receivers, it is enough to provide one distribution point combined with one of the transformer substations. In all cases, it is recommended to power the receiving points by the deep insertion method, the number of inputs (in the presence of electrical receivers of the first category) should be at least two.

For powering industrial enterprises, GPP and workshop transformer substations TP with the simplest block diagrams without buses and switches for primary voltage. An exception to the rules are TPs combined with RP, for which one or two bus sections with automatic backup input (ATS) are provided at the primary voltage for receiving and distributing electricity when powering electrical consumers of the first and second category or without ATS when powering of electrical receivers of the third category.

For more information on the categories of industrial receivers in terms of power reliability, see here: Electricity receivers

In distribution and distribution substations indoors 6-10 kV, including for powering electrical consumers of the first category, one bus system is used. Sectioning and automatic redundancy are provided for continuous power supply of electrical consumers of the first and second category.

Switching of low and medium power connections at a voltage of 6-10 kV is carried out using load breakers complete with supply fuses or without them within the parameters of nominal mode and short-circuit mode. The installation of switches at the entrances and sections 6-10 kV is provided for automatic transfer switches, as well as for large substations with a capacity of 5000-10 000 kVA and more with the number of outgoing feeders 15-20 or more. In other cases, disconnectors or load-disconnectors are installed at the inputs and disconnectors at the sections.

Voltage selection

When the voltage of the supply lines is not higher than 10 kV, the voltage of the local networks is assumed to be equal to the voltage of the power source. When receiving energy from a power source with two or more voltages or designing enterprises with more large power, necessitating expansion of existing regional substations or power plants, supply line voltages are selected on the basis of technical and economic calculations.

In industrial enterprises, the most common voltages (kV):

-

for feeder lines 110, 35, 10 and 6,

-

for distribution networks 10, 6 and 0.4 / 0.23.

Until now, a voltage of 10 kV is recommended for wide use in all cases, especially when there are few 6 kV motors in the plant. In this case, 6 kV motors are connected to a 10 kV network via 10/6 kV intermediate conversion transformers.

The main voltage for power supply and lighting of electric receivers of the industry is 0.4 / 0.23 kV.

See also: Choice of number and power of transformers

Selection of power distribution schemes for voltage 6 — 10 kV

This choice depends on the territorial distribution of the loads, their size, as well as the required degree of reliability of the power supply.

In the practice of designing the power supply of industrial enterprises, schemes for radial and trunk power distribution are used, but the latter are not used enough and not to the full extent.

Radial schemes are recommended in the following cases:

-

single-stage with one radial line - for powering isolated large concentrated loads (for example, 1000 kW synchronous motors for driving milling machines in the woodworking industry) and loads placed in different directions from the power source,

-

two-stage with two radial lines — for power supply through RP of workshop substations and motors with voltages above 1000 V (for example, RP in the main building of the workshop).

When the substations are located favorably for the straight-line passage of the electrical network (without return passages, long bypasses of buildings, etc.), single networks without reserves are used to supply single-transformer substations with energy consumers of the third category.

If there are 15-30% loads of the first and second categories in these substations, the power supply of adjacent single-transformer substations from different single highways is used for mutual backup of a jumper with a voltage of up to 1000 V.

Dual end-to-end circuits with unidirectional power supply are used to power substations with two sections of busbars and two-transformer-less substations with power receivers, mainly of the first and second category.The number of transformers with voltage up to 10 kV connected to one main line should be taken 2 — 3 with their power 1000 — 2500 kVA and 3 — 4 lower powers.

Typical schematic power supply schemes of industrial enterprises

A rationally implemented power supply scheme should ensure:

-

reception and distribution of electricity in accordance with the load schedule of electricity consumers,

-

the required degree of power supply reliability,

-

the possibility of increasing the load during the expansion and reconstruction of the enterprise,

-

efficiency, comfort and safety at work,

-

appropriate voltage level of power consumers.

The development of a power supply scheme should be based on the following data:

-

electrical loads, voltages and categories of electrical consumers of electricity consumers,

-

territorial distribution of loads and large power receivers according to the master plan, the number and capacity of substations,

-

characteristics of power supplies,

-

technical specifications of the power system,

-

Emergency mode requirements.

When developing a power supply scheme, it is necessary to take into account:

-

recommendations for the selection of parameters and elements of the power circuit,

-

necessary limitation of short-circuit currents, as well as conditions for performing simple and reliable relay protection, automation and remote control,

-

the overload capacity of transformers and cables, as well as the degree of redundancy in the technological part,

-

the prospects for the development of the enterprise in the next 10 years.

The schemes take into account the specifics of the industry.They must guarantee the efficiency and reliability of the enterprise's power supply.

Examples of schemes for single-line power supply for industrial enterprises at a voltage of 6 - 10 kV are shown below.

Power schemes for industrial enterprises at voltage 6 — 10 kV

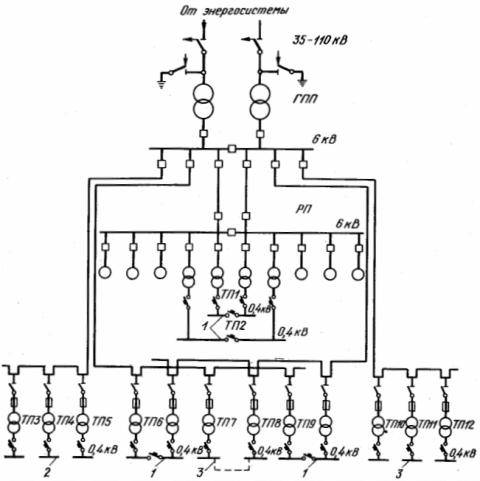

Rice. 1. Power supply scheme at a distribution network voltage of 6 kV. Category of liability of consumers of electric energy: 1 — first and second, 2 — third, 3 — second and third

The power supply diagram shown in fig. 1, it is recommended to be used in medium-sized enterprises (installed power from 5 to 75 MW), which include installations and workshops with 10 kV electric motors, the load of which is about 50% of the enterprise load, with the possibility of direct power supply to them with voltage 10 kV (own GPP, external power supplies with voltage 10 kV).

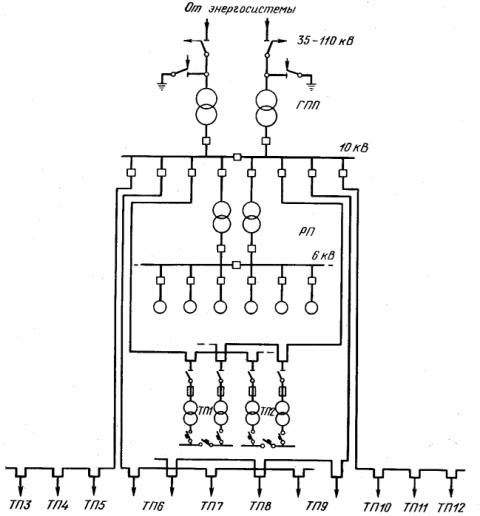

Rice. 2. Power supply scheme at a distribution network voltage of 10 kV

The power supply diagram shown in fig. 2, at this stage it is advisable to apply it in the same enterprises if the total load of 10 kV from the electric motors of workshops and installations is significantly less than 50% of the enterprise load.

Supply circuits with split windings of transformers are not taken into account, since the power of transformers installed in gas transmission installations of industrial enterprises is usually below 25 MBA, i.e. the power of transformers manufactured with split windings. In these schemes, preference is given to the main power supply schemes of TP as the most economical.

Power supply diagrams in fig. 1 and 2 are generalizations, therefore in specific cases circuit elements (mainly related to 6 kV motors) may be missing.

See also on this topic: Schemes for internal power supply of enterprises for 6 — 10 and 35 — 110 kV and Typical power supply schemes for enterprises