Reliability in the power industry — basic concepts and definitions

What is reliability

The reliability in the operation of the electrical equipment of the power supply systems is one of the most important factors that have a significant impact on the economic indicators of the energy complexes in the country.

The costs of interruption of the power supply in case of emergency downtime constitute a significant part of the total costs of production and installation of a power supply network, and for the population such an accident leads to great moral shocks. In this regard, the issues of improving the methods of operation of electrical equipment in power supply systems at different levels are particularly relevant. Therefore, a feature of the modern electric power industry is the increased requirements for the reliability of the power supply and the quality of the power.

Forecasting the reliability of power system facilities as well as developing strategies and planning, upgrading and repairing electrical equipment are priority tasks of the state.The modern approach to solving these questions is based on the application of reliability theory methods and optimization of the operation of complex technological objects.

Reliability is built into the design, guaranteed during manufacturing, and expended during operation. It should be borne in mind that reliability indicators allow you to assess the state of an average object. This leads to the fact that in one case underestimated values are obtained, and in the other - overestimated values. Technical diagnostics allows you to assess the condition of a specific object. Knowledge of the actual state of the object is provided through its control — monitoring.

When designing, the electrical installation must be created adapted to the diagnosis and recovery, during production—operational and during operation—to ensure the maintenance of an operational state. Diagnostic methods and tools are a tool for maintaining a given reliability.

Understanding the basics of the theory of reliability and technical diagnostics, familiarization with the methods and means of diagnostics of elements contributes to the correct decision-making in the design and operation of electrical equipment in power supply systems.

Electrical installations are considered as an object, which is understood as a set of machines, devices, power lines (power lines), intended for the production, transformation, transmission, distribution of electrical energy and its conversion into another type of energy.

Power plants include: generators, power transformers, autotransformers, reactors, voltage and current transformers, power lines, distribution devices, entire transformer substations (KTP), distribution networks, electric motors, capacitors, automation and protection equipment, various energy receivers.

Basic concepts and definitions

The analysis of the set of recommended terms for the reliability of power systems shows that if, in order to describe the reliability of the elements of power systems and their electrical networks, the formulations in the proposed terms fully adequately describe the properties of electrical and electrical network equipment as elements, then to describe the reliability of a power system as a system, these terms are incomplete and sometimes even distort the technological essence of the described systems.

Adopted wordings: Reliability — the property of the object to perform the specified functions, maintaining over time the values of its performance indicators within the established limits, corresponding to the specified modes and conditions of use, maintenance, repair, storage and transportation.

Therefore, a more complete formulation of the "reliability of the power system" sounds like this: "According to the basic provisions of the theory of reliability, the reliability of the operation of the power system should be understood as its property to maintain the ability to perform the intended functions in any time interval, regardless of the impact of external conditions. «

A reliable power supply requires that all elements of electrical installations, including generators, transformers, feeders, automation, protection and distribution equipment, operate smoothly. Each of the elements of the electrical installation contributes to the reliability of the power supply.

Power supply reliability — the property of electrical installations to provide consumers with electrical energy according to their category… According to the conditions of power supply reliability, all users are divided into three categories.

Category I electrical receivers — electrical receivers, the interruption of the power supply of which can lead to danger to human life, damage to expensive basic equipment, defects in the mass product, disruption of the functioning of particularly important elements of public services. A special group of electrical receivers is distinguished from the composition of this category, the continuous operation of which is necessary for a smooth shutdown of production in order to prevent threats to human life, explosions, fires and damage to expensive equipment.

Category II electrical receivers — electrical receivers, the interruption of the power supply of which leads to a mass shortage of products, downtime of working mechanisms and industrial transport, disruption of the normal activities of a significant number of people.

Category III electrical receivers — all other electrical receivers not meeting the definition of categories I and II.

In the field of power supply systems, reliability is understood as a continuous supply of electricity within the limits of permissible indicators of its quality and the exclusion of situations that are dangerous for people and the environment. In this case, the object should work.

Operability — the condition of the elements of the electrical equipment in which they can perform the specified functions, while maintaining the values of the main parameters within the limits established by the normative and technical documentation. In this case, the elements may not meet, for example, requirements related to appearance.

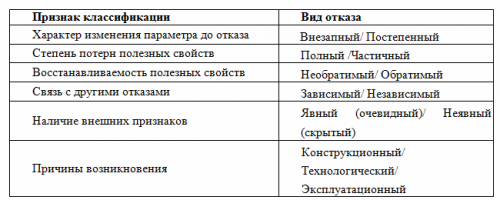

An event involving an equipment failure is called rejection… The causes of damage can be defects made during design and repair, violations of rules and operating rules, natural wear processes — different types of damage are distinguished based on different classification characteristics (Table 1).

Table 1. Classification of damage

By the nature of the change in the main parameters of the electrical equipment before the occurrence of the failure, sudden and gradual failures are distinguished.

Suddenly — damage that occurred as a result of a sudden sharp change in one or more basic parameters, for example: phase failure of cable and overhead lines, destruction of contact connections in devices.

Gradually is called damage that occurs as a result of a long-term, gradual change in parameters, usually due to aging or wear, for example: deterioration of the insulation resistance of cables, motor windings, increase in contact resistance of contact connections. In this case, the parameter changes in comparison with the initial value can in many cases be recorded using measuring instruments.

There is no fundamental difference between sudden and gradual failures, since sudden failures in most cases are the result of a gradual, but hidden from observation, change in parameters (for example, wear of mechanical assemblies of switch contacts), when their destruction is perceived as a sudden event.

Complete rejection characterizes a non-working object that does not perform any of the specified functions (there is no lighting in the room - all lamps are burned out). In case of partial damage, the object performs some of its functions (several lamps burned out in the room).

Irreversible damage shows performance loss (burnt fuse).

Reversible — Repeated only correctable failure of object a (fluorescent lamps on, then off).

Disruptive — repeatedly self-eliminating damage to an object.

If the failure of an object is not due to the failure of another object, then it is considered independent, otherwise - addicted… If during the inspection a damaged element is found (the insulation of the wire is destroyed), then the failure is considered explicitly (obviously)… If during the inspection it is not possible to determine the cause of the failure in the damaged electrical equipment, it is considered a failure hidden (hidden).

Failure as a result of violation of established design standards is called structural as a result of violation of operating rules — operative… Malfunction that occurred as a result of an imperfection or violation of the established process of production or repair of an object carried out in a repair facility — technological (production).

Reason for refusal — defect… Differentiate: the failure of an element of a complex object (a blown fuse in the supply network of the apartment), the appearance of new connections between the elements (a short circuit has occurred), a violation of communication between the elements (wire breakage).

Reliability is manifested only during operation. Depending on the specifics of electrical installations and the conditions of its operation, reliability (in the broadest sense of this term) may include a set of such properties as reliability, durability, maintenance, storage separately or in a certain combination, both for electrical installations and for its individual elements.

In a narrow sense, reliability equates to reliability (in the "narrow sense").

Reliability — the property of technical objects to maintain continuous operability for some time. It is the most important component of the reliability of electrical installation elements, depending on the reliability of the elements, their connection scheme, structural and functional characteristics and operating conditions.

Endurance — the property of the technical objects to remain in operation until the occurrence of the limit state with the established maintenance and repair system.For the elements of an electrical installation, the limit state is determined by the impossibility of their further use, which is due either to a decrease in efficiency, or to safety requirements, or to the onset of obsolescence.

Support — a property that allows you to detect and prevent the causes of damage, as well as eliminate their consequences through maintenance and repair. Maintenance characterizes most elements of power plants and does not make sense only for those elements that are not repaired during operation (for example, insulators of overhead lines).

Persistence — the property of technical objects to continuously maintain a serviceable (new) OR serviceable condition during storage and transportation. The preservation of electrical installation elements is characterized by their ability to withstand the negative effects of storage and transportation conditions.

The choice of quantitative indicators of reliability depends on the type of power equipment. Non-recoverable are those elements of the power plant, the performance of which in case of failure cannot be restored during operation (current transformers, cable inserts). Their reliability is characterized by reliability, durability and preservation.

Recoverable — objects whose operability in the event of damage is subject to restoration during operation. Examples include electrical machines and power transformers. Reliability of remanufactured products is due to their reliability, durability, maintenance and storage.